Estonian scientists are transforming fishing industry by-products into usable resources like wound dressings and leather-like materials, thanks to EU support. The project focuses on turning fish waste, including inedible parts such as skin, bones, and heads, into valuable raw materials like gelatine, chitin, and chitosan, which are then processed into nanofibres for various applications.

The fishing industry generates significant waste, including solid and liquid by-products, with operators facing challenges in disposing of these materials. The costs associated with waste disposal and the overlooked potential of these by-products are persistent issues. While extracting raw materials from waste is not a new concept, the project aims to go beyond traditional uses of substances like gelatine, chitin, and chitosan, which have applications in food, medicine, and cosmetics.

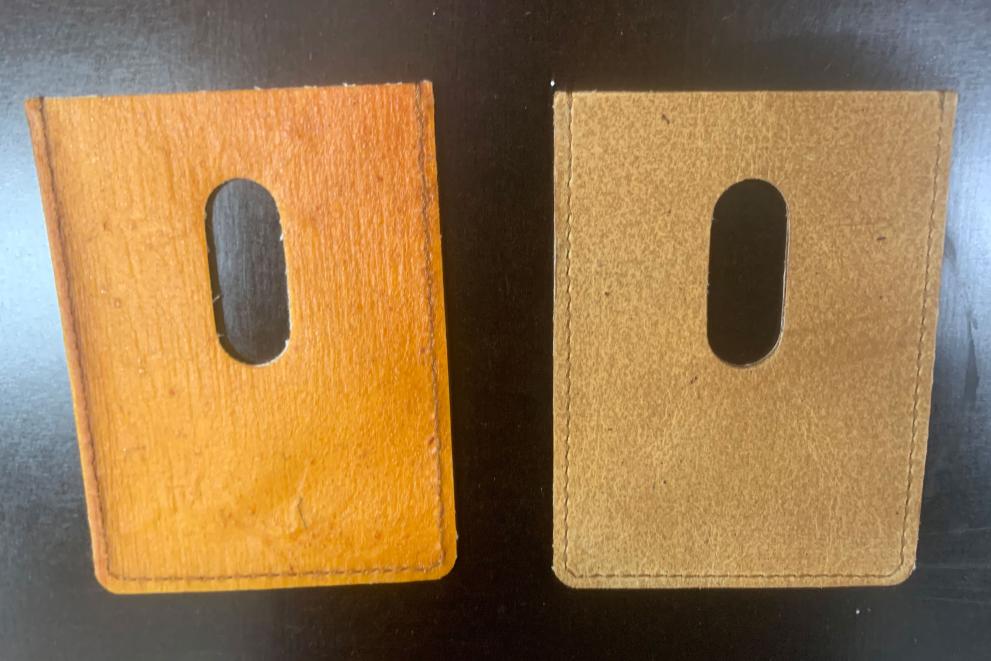

This initiative focuses on extracting and converting these materials into nanofibres suitable for uses in wound dressings and leather-like fabrics. The team has also demonstrated the production of fish gelatine-based business card pockets and medical patches. The research is supported by EU funding, with collaboration from multiple stakeholders. Fish processing company Latikas OÜ provided waste and insights, while scientists from the Estonian University of Life Sciences developed extraction methods and explored alternative uses for fish gelatine.

Additionally, researchers from the University of Tartu’s Institute of Pharmacy played a key role in testing the nanofibre production process. Their work has led to the development of fish gelatine-based wound dressings that meet pharmaceutical standards, which are being introduced to clinical settings through the spin-off company EsaDres. Meanwhile, Gelatex Technologies OÜ, an Estonian company, has enhanced the gelatine extraction process and developed innovative gelatine-based textile materials.

This project represents a significant step towards the circular economy, turning waste into valuable biopolymers that can be processed into sustainable products. The project highlights the untapped potential of fishing industry by-products and paves the way for further innovations in sustainability.