Ready for the 2D migration? It’s the start of a new chapter in the global supply chain creating opportunities for efficiency, innovation, and value.

The GS1 initiative is reshaping product marking and retail checkout systems. Leading FMCG producers and retailers have already committed to adopting the GS1 2D code standard and are actively driving its development.

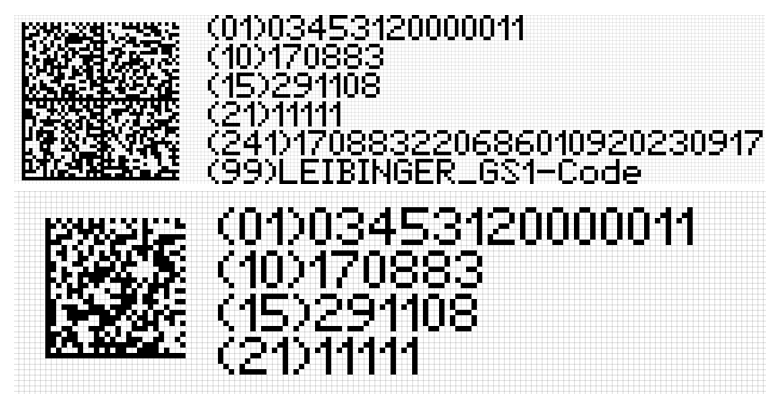

By 2027, industry will enter the pilot phase with a gradual adoption of 2D codes. A 2D code can store up to 7,000 numeric characters, including: net weight, expiration dates, serial and batch numbers. All of this data can be embedded in a single 2D symbol that is faster and easier to scan from any angle.

The two most widely used 2D code formats are: QR codes (GS1 Digital Link URI) and GS1 DataMatrix codes (square or rectangular). Both formats provide high data density in a small space while remaining as fast to scan as linear barcodes.

Are 2D codes harder to print?

Yes — compared to linear barcodes, 2D codes are more complex. They contain much more data and are made up of dense arrays of small modules. While most printers can technically apply a 2D code, the real challenge is printing with maximum readability, at high speed, and at low cost.

In fast-paced industrial production, selecting the right technology — and the right solution partner — is essential.

What effect does this have on production speed?

This has a significant effect on production speed. LEIBINGER CIJ printers have the fastest drop generators on the market (up to 96,000 drops/second), which is why they are often preferred by ultra-fast extruded cable manufacturers, operating at 1,000m/min.

The latest LEIBINGER IQJET reliably prints 2D codes at speeds of up to 20,000 codes per hour and offers the market’s maximum printhead height — 15 mm. It prints GS1 QR versions up to 33×33 modules in line. A UV laser printer requires 13 passes to print a single black square on a GS1 2D code: CIJ printers print the same barcode square with a single drop of ink.

Will 2D codes affect the cost of printing?

The technology chosen to meet the demands of 2D codes will affect overall running costs.

Add to this the lower purchase price of continuous inkjet technology and it has some compelling cost advantages. Bear in mind also that low energy consumption and frugal use of solvent makes CIJ printers more sustainable – whereas laser printer users need to dispose of non-recyclable used filters every few months. You can have highly legible 2D codes whilst also reducing operating cost and CO2.

In fact, the IQJET delivers unbeatable TCO with the lowest cost per code on the market. Additional savings come from consistently high uptime, ensured by automatic nozzle sealing and 5 years of maintenance-free operation.

Are you ready for the 2D migration (GS1 Sunrise 2027) initiative?

The seamless transition to 2D codes is an amazing opportunity for producers to streamline logistics and improve the customer experience. And there is no reason that these benefits should come at a cost. At LEIBINGER, we have looked into the technicalities of 2D barcode printing and we are confident that our CIJ printers offer an excellent way for you to make the most of the 2D barcode opportunity – and greet the 2D migration with confidence!

All images shown in the article are original prints of 2D codes produced by LEIBINGER CIJ printers.