Labels sometimes decide whether a bottle of wine, a piece of meat, apples, broccoli or a pack of cookies are carried to the checkout or back to the shelf by a consumer. Smart design, ingredients, dates of expiry, prices, filling quantities or origins are all relevant. Data on labels enable correct distribution, traceability, seamless workflows and economic calculability along the supply chain.

For communication to work, the quality of a label material, comfortable look and feel, clearly visible data, legible printing and smooth and precise label application each play a major role. Industrial companies request for labeling systems that achieve high processing speeds even with items following each other in quick succession on a conveyor. Whether an item is in motion or at rest at the time a label is applied and from which side labels are transferred are further factors. cab print and apply systems do all these. They also add variable data onto pre-printed labels, stick labels precisely to smallest spots, do linerless or smart labels. The long-established German company has been constantly developing its equipment. Farmers, food and beverage businesses, retailers and wholesalers benefit.

Containers

You get bottle labels in all shapes and sizes. On the neck and chest of a bottle, they give an identity and promote a brand. Next to design, obligations are important. Bottles put into circulation by brewers and beverage companies must have been identified in accordance with regulations. Amongst others, manufacture data, dates of bottling, article and LOT numbers, nutritional and alcohol values must be mentioned on the back of a bottle. Such ID is usually checked by scanners. Misinformation is a no-go. Consumer protection and quality assurance are main arguments.

You get bottle labels in all shapes and sizes. On the neck and chest of a bottle, they give an identity and promote a brand. Next to design, obligations are important. Bottles put into circulation by brewers and beverage companies must have been identified in accordance with regulations. Amongst others, manufacture data, dates of bottling, article and LOT numbers, nutritional and alcohol values must be mentioned on the back of a bottle. Such ID is usually checked by scanners. Misinformation is a no-go. Consumer protection and quality assurance are main arguments.

High performer, right on the mark

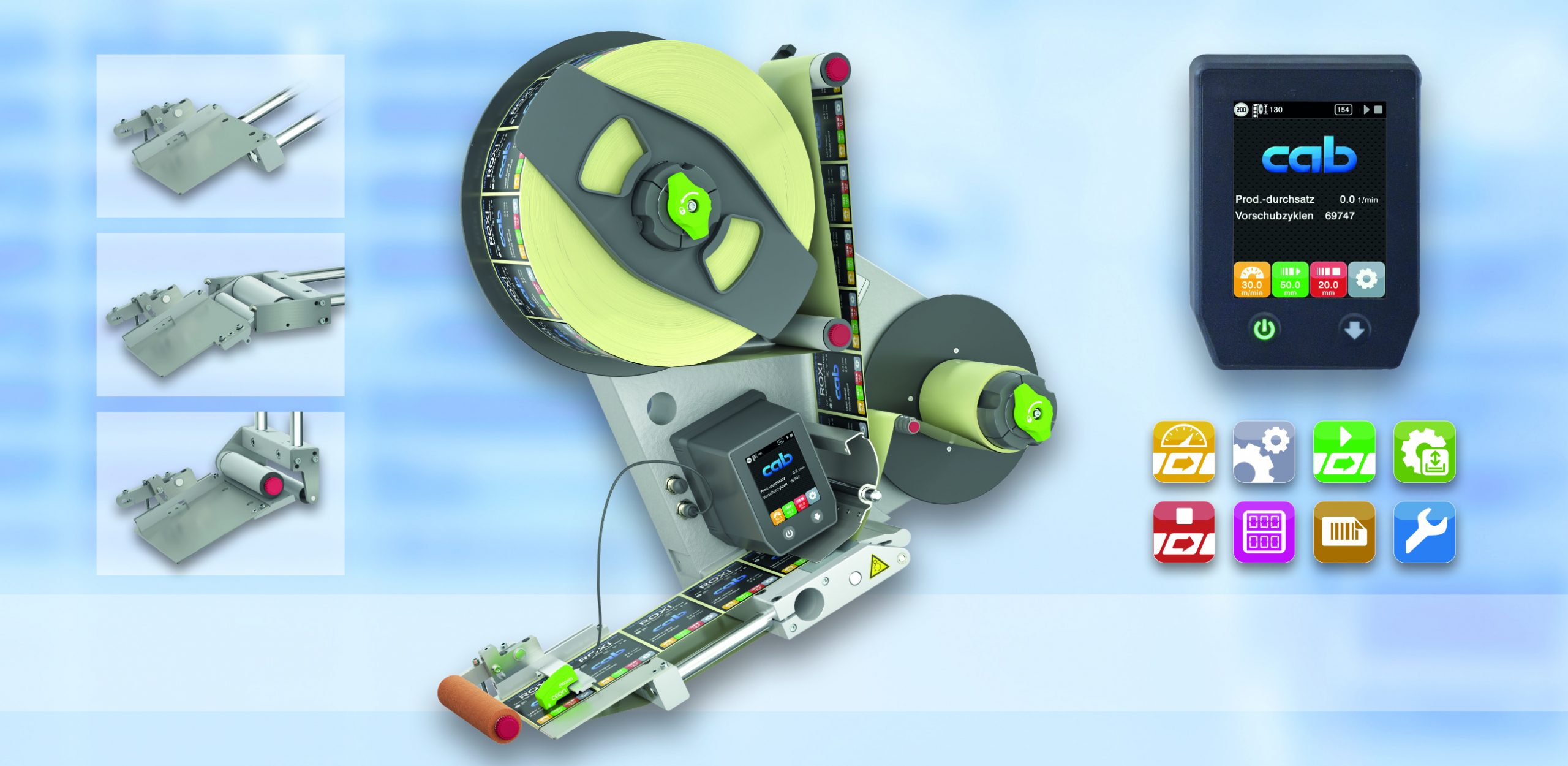

cab has just introduced ROXI, an automatic label dispenser. It is based on the tried and tested mechanics of industrial cab HERMES printers and the trailblazing firmware of cab applicators. Printed self-adhesive labels can be dispensed fully automatically in linear and rotary plants. The labels are fed in accordance with the speed of an item on a conveyor thanks to a rotary or linear master encoder. Precision is guaranteed when labeling at speeds as high as 30 meters per minute. Different demand units suit for various surface conditions. Columns, stands and connecting cables allow the “workhorse” to be installed ready for use in any motion cycle. As required, PX Q print modules add variable data individually onto pre-printed decorative labels, supplied in subsequence to ROXI for application.

cab has just introduced ROXI, an automatic label dispenser. It is based on the tried and tested mechanics of industrial cab HERMES printers and the trailblazing firmware of cab applicators. Printed self-adhesive labels can be dispensed fully automatically in linear and rotary plants. The labels are fed in accordance with the speed of an item on a conveyor thanks to a rotary or linear master encoder. Precision is guaranteed when labeling at speeds as high as 30 meters per minute. Different demand units suit for various surface conditions. Columns, stands and connecting cables allow the “workhorse” to be installed ready for use in any motion cycle. As required, PX Q print modules add variable data individually onto pre-printed decorative labels, supplied in subsequence to ROXI for application.

Thermal transfer

This print method sees a print head selectively heating a special ribbon. Melted color transfers onto the material to be printed. This process is economical in particular with large label volumes. Provided that proper materials are in use, thermal printing remains legible during the processing of goods, inspection, picking, stock and transport. cab only provides tested ribbons of wax and resin qualities, as well as their mixtures. Such ribbons dissipate heat best possible to protect the print head of a cab printing system. Special backcoating prevents from wear, thus, electrostatic charging.

Appropriate labels

Users may benefit when purchasing labels from the same supplier as a printer or applicator. Productivity will increase for sure. The surfaces of labels provided by cab are optimized for highly detailed thermal transfer printing. Diameters of rolls and cores match with cab printers, so does the winding. cab recommends polyethylene, PE, for bottles. In comparison with other synthetic materials, such labels are particularly flexible and conformable. Resistance to oils and fats takes into account the sometimes harsh conditions in bottling halls. Different temperatures prevail before, during and subsequent to bottling. Labels must withstand these and condensation without losing shape, peeling or wrinkling. Bottled containers touch each other on a conveyor. The label material selected should therefore prevent from wear and tearing. This also applies to distribution and further transport on pallets, preferably in crates, cardboard boxes or six-packs.

Fruit and vegetables

cab HERMES and SQUIX units are popular in the industry. Their printing units can be combined with any cab standard applicator or a robot. These automatically transfer labels onto an item after printing. Sample applications are as follows:

cab HERMES and SQUIX units are popular in the industry. Their printing units can be combined with any cab standard applicator or a robot. These automatically transfer labels onto an item after printing. Sample applications are as follows:

- Curvy ones, eco-efficient: When labeling cucumbers, a form pad on the applicator clings to their organic, cylindrical shape. Bubbling is avoided. The cucumbers touch each other during transport and display. Industrially compostable labels are food-safe and protect the environment.

- Fruit on the run: Apple trays sealed in foil are a classic display. They are labeled by an air jet box. This applicator bridges distances as wide as 20 centimeters using a blast of air. The apples are not touched. Landed labels stuck to the surface of a package. No pressure is exerted to the fruit.

- “White gold”, bundled up: Rubber bands around asparaguses get label flags. Printed labels are therefore precisely glued by a pair of pliers on their endings and then pressed onto the rubbers. The latter are entirely enclosed.

- Identities out of the box: On wooden or synthetic orange crates, labels in side pockets provide information. They link to the next processing step. Continuous cardboard webs are particularly stable. Perforation enables several lanes to be arranged on the material, resulting in high throughput. Printed materials can be cut, lanes be separated easily by hand along perforation.

Ecological footprint

Needs for green supply chains are growing. According to cab, there are several reasons for this. Guidelines in industry are changing. Customers, business partners and suppliers demand proof in procurement. Companies are feeling the pressure of improving existing practices to conserve resources. At this, HERMES QL linerless print and apply systems stand out. They enable packing using logistics labels without liner material. Tons of waste are eliminated worldwide. The ecological footprint is significantly reduced. As continuous label materials require fewer changeovers, system downtimes are reduced. Direct thermal printing uses special thermal-sensitive paper. This method eliminates the need for ribbons and therefore provides further sustainability and a low-maintenance alternative when labeling in logistics. Industry and the environment benefit. All linerless continuous materials provided by cab are free of bisphenols and suit for use in the food sector. What entrepreneur would not be pleased to see ecological balance as a guarantee of economic efficiency?

Needs for green supply chains are growing. According to cab, there are several reasons for this. Guidelines in industry are changing. Customers, business partners and suppliers demand proof in procurement. Companies are feeling the pressure of improving existing practices to conserve resources. At this, HERMES QL linerless print and apply systems stand out. They enable packing using logistics labels without liner material. Tons of waste are eliminated worldwide. The ecological footprint is significantly reduced. As continuous label materials require fewer changeovers, system downtimes are reduced. Direct thermal printing uses special thermal-sensitive paper. This method eliminates the need for ribbons and therefore provides further sustainability and a low-maintenance alternative when labeling in logistics. Industry and the environment benefit. All linerless continuous materials provided by cab are free of bisphenols and suit for use in the food sector. What entrepreneur would not be pleased to see ecological balance as a guarantee of economic efficiency?

Anything possible

As a result of the possibilities of machine networking and automation, requirement profiles in packing and bottling systems have changed, warehouse included. Digital work steps are now part of everyday life. On this occasion, cab systems work autonomous, interact with each other, host computers or a plant control system. Technological changes and markets in transition are key concerns. They result in a high level of complexity and make labeling an exciting topic constantly evolving. Development, manufacture and commercial processes are set by cab in accordance with requests for flexibility and individual solutions. Experienced experts support user-specifically from initial consultation to the configuration of a print and apply system and its implementation in a company.

To learn more about cab, please visit http://www.cab.de/en