Are more traditional rigid packaging formats causing food processors and food service companies to miss out on operational and sustainable performance benefits? Riccardo Castagnetti, Executive Director of Fluids Platform at SEE, takes a look at why businesses may want to think again about their approach to flexible food packaging.

Overlooking flexible food packaging

Metal cans and plastic cartons are some of the rigid packaging formats widely used by food processors and service companies. These solid materials are often chosen as the hard outer surfaces are perceived to offer good protection.

In some instances, rigid packaging is also selected for sustainability reasons, with materials such as glass and hard plastic being widely recycled. These circumstances mean rigid packaging has become so dominant, that it overshadows flexible packaging being considered as an option by food processors and service companies. Consequently, businesses may be missing opportunities to enhance efficiencies, productivity, and sustainable practices.

Lower environmental footprint

Flexible packaging can use up to 75% less energy and produce one-tenth of the amount of CO2 emissions, compared to metal cans. Additionally, The Flexible Packaging Association reports that flexible packaging requires less water and energy to manufacture, and that efficiencies in product-to-pack ratios can reduce food waste.

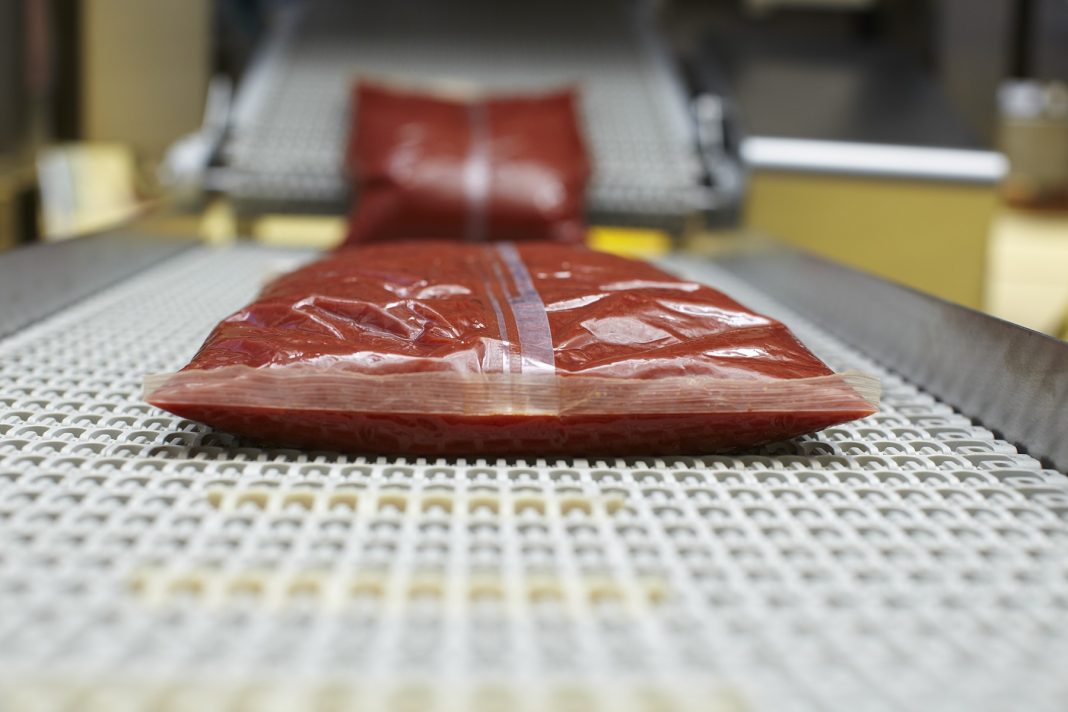

Innovative technology like SEE CRYOVAC® brand FlexPrepTM portion dispensing pouches offer up to 98% yield for condiments, sauces, and toppings. Higher volumes of the liquid food content can be utilised to reduce waste going to landfill, while optimising product usage can also benefit operating budgets and profit margins. Flexible packaging can help yield around 20% more product than rigid packaging alternatives.

Minimising environmental impact also continues at the end-of-packaging-life. Advances in materials means many of the CRYOVAC® brand vertical-fill-seal flexible packaging films are compatible with LDPE RIC4 recycling streams*. This can satisfy demand for recyclable materials. Any waste disposal, and associated carbon emissions, can also be reduced. Flexible packaging is easily compactable – much more so than rigid alternatives. Lower volumes of waste are created, resulting in less landfill space and fewer waste collections.

Lightweight, flexible food packaging can also generate transport savings. Packaging formats, such as pouches for soups, sauces and even ground meats, occupy less space and are easier to transport than rigid containers. Higher volumes of products can be carried per vehicle to reduce the number of deliveries and trucks on roads. Similar savings can be made earlier on in the supply chain at the pre-packaging stage. Flexible packaging can be transported flat or on rolls, so that it uses much less vehicle space than empty metal cans or hard plastic cartons being delivered to a processor for filling.

More flexible performance

Space saving efficiencies continue on-site. Flexible packaging can occupy up to 40% less space than metal cans. This allows for valuable areas to be utilised for core operations and can also positively impact inventory management and productivity. For food services operators, this additional capacity could be dedicated to storing more liquid food products to maintain preparation and cooking activities. For food processors, being able to conveniently store a readily available supply of packaging can help uphold continuous throughput and avoid production-line bottlenecks.

Food processors can further optimise floor space through vertical form-fill-sealed flexible packaging equipment, which tend to be more compact than horizontal rigid filling systems. Innovative systems are also able to produce packages at faster rates than most rigid container filling systems. For example, the new CRYOVAC® Vertical Form-Fill-Seal Equipment 308 can produce 28 packs per minute. The solution can produce a range of pack sizes, from 250ml up to 2 litres, and is suitable for both cold and hot fill applications up to 95°C. This level of versatility can yield further efficiencies for food processors through quicker product changeovers and lower levels of scheduled downtime.

Maintaining product protection

The efficiencies and sustainable performance of flexible packaging can be utilised by food processors and service companies, while still maintaining outstanding levels of product protection. Packaging films and pouches offer excellent resistance against punctures and tears. Any risk of leaks and spillages is further minimised through secure, high-integrity seals. Combined, these features help prevent spoilage and wastage, and protect food flavour and texture.

There may also be packaging applications, where a flexible pouch provides greater levels of protection than rigid containers. For example, a plastic carton containing sauces and dressings, may be more susceptible to cracks and breakages when dropped, compared to a more flexible material.

Advances in flexible food packaging solutions continue to accelerate at pace and are well worth considering versus more traditional rigid packaging formats. In many cases, food processors and service companies could find that making a small switch to flexible food packaging is an effective step towards improving operational and environmental performance.

*Recycle-ready films have varying degrees of recyclability depending on the scope and availability of collection, sortation, and recycling programs.