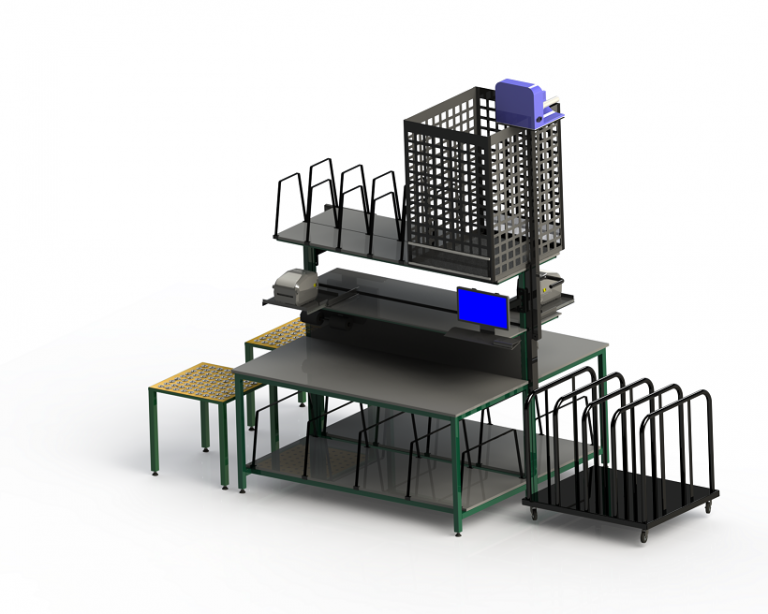

Kite Packaging launches custom packing benches

The leading online UK packaging supplier has launched modular custom packing benches. These are made from ready-built units to the customer’s specification for a bench which better suits their industry, operation and environment.

The benches are available in widths of 1200mm and 1800mm and are constructed from 40mm box steel which is welded together, ensuring maximum strength and durability for all high usage applications. The fully-faced, wipe-clean melamine worktop is hardwearing and able to withstand busy pick, pack and despatch areas.

Customisation options include extra shelves for greater storage, adjustable toast racks for organisation and a void fill hopper for storage. Customers can also add a choice of two small side tables as well as a printer tray for attachments, keyboard tray and monitor arm for those using warehouse management systems. These features ensure employees have the right materials and tools to hand, enabling them to efficiently and securely pack items.

Kite’s custom packing benches are well-designed, of high quality and built to last, providing employees with a user-friendly packing area which is tailored specifically to their requirements, making their job quicker and easier.

To learn more about the products and services available at Kite Packaging, please visit www.kitepackaging.co.uk.

interpack 2023: ROTZINGER Group presents expanded packaging and processing portfolio

At interpack, the ROTZINGER Group will be presenting its expanded packaging and processing portfolio for the first time. The Paloma feed placer, the FLK/VRM Filling & Capping machine, the TLT blister machine in a new compact design as well as a bar production line will be among the highlights at booth C07 in hall 1. Visitors can also learn about the company’s digital solution that can be customized to individual needs.

Paloma: outstanding pick and place accuracy and new layout possibilities

“Paloma is our high-performance robot cell that offers outstanding pick and place accuracy,” says Christian Vouillamoz, product manager at the ROTZINGER Group. The Paloma feed placer picks and places products into cartons, cases, thermoforms, flow-wrappers and cartoning machines. Using vision-guided high-speed delta robots, the machine identifies incoming products on the conveyor belt and places them correctly into the feeding of the following process. The system can handle both unpacked and packed products and its modular design allows to directly integrate an infeed chain of the packaging machine (horizontal or vertical) into the cell and to load it with oriented products. Paloma is perfectly suited for food and confectionery applications and can be used in many areas such as bakery or fresh products – and offers new lean layout opportunities when combined with a new integrated buffer.

Filling and capping with maximum flexibility

In terms of filling pharmaceutical and cosmetic products, the ROTZINGER Group’s Filling & Capping machine FLK/VRM truly stands out. The machine combines the advantages of a linear filler and a rotative capper, offering maximum flexibility and efficiency. Any product from water-like to vicious and sticky liquids can be filled with the volumetric and mass-flow filling system and it can easily be adjusted for different formats.

High-performance blister machine with new compact design

ROTZINGER further unveils a new and improved version of their TLT blister machine that can process up to 400 blisters per minute. “This machine is a proven and reliable solution and we are excited to bring it back,” says Andreas Graf, CEO of ROTZINGER PharmaPack. The TLT has undergone a redesign and is characterized by its flexibility, safety, short changeover times, while maintaining high Overall Equipment Effectiveness. For the primary packaging of pharmaceutical products, the TLT is a flexible machine that can be connected to several cartoners. Customers benefit from the modular design for simple and easy retrofitting. The TLT has a clear separation of the production and drive areas, and even offers optional complete encapsulation of the product feed zone to ensure compliance and protect the product and packaging material. The TLT’s user-friendly interface with a simple color touch screen simplifies machine operation and reduces the risk of misuse. It is an ideal choice for packaging various pharmaceutical products such as tablets, capsules, and dragees using standard thermoforming and aluminum foil.

Higher flexibility and less product waste in bar production

In bar production, manufacturers can maximize their productivity levels with a single-source solution for the entire process from processing up to secondary packaging. The ROTZINGER Group will showcase the unique WRL Flex slitter developed by HANSELLA, which has been part of the ROTZINGER group since 2021. The WRL Flex slitter offers an adjustable cutting width. As a result, adjusting the cutting width can be done with minimal effort and without changing parts. Besides higher flexibility, this decreases production costs and contributes to faster return on investment (ROI). The smooth slitter allows for an easy and stepless adjustment for precise cutting to produce different bar sizes. Unlike other machines of its kind available in the market, the WRL Flex enables repeatable cutting width changes without the change of the cutting knife shaft or the complete slitter. This reduces set up times significantly. In addition, manufacturers benefit from a hygienic design and easy tool-less cleaning.

When processing bar masses including cereal, candy, protein and fruit, the patented flexible WRF Flex slab former eliminates the trim. Less product is wasted, contributing to decreased production costs and faster return on investment (ROI). The WRF slab former is the only roll former on the market on which the width of the mass slab can be precisely and continuously adjusted without interrupting the production process. The phenomenon of lower density at the edges is solved by forming a correspondingly wider slab and then compressing it to the finished width. Depending on the type of bar, trim can either be reduced to an extreme minimum or completely eliminated with our flex solutions.

ROTZINGER’s chocolate enrober provides a quick mass changing system for chocolate when coating bars. The removable and exchangeable mass trough as well as the exchangeable enrobing head and curtain device ensure mass changes in minimal time – to complete the efficient enrobing portfolio, ROTZINGER also offers chocolate melting and tempering units. “The Rotzinger Group combines many years of experience within the group and offers a turnkey solution from the bar line process to secondary packaging with highest efficiency along the line,” explains Adrian Müller, Director Product Management/ Marketing.

Digital Factory Software Suite increase efficiency and quality

Visitors to the ROTZINGER Group’s booth at interpack will have the opportunity to witness the company’s digital solutions firsthand. For example, the Digital Factory Software Suite promises to increase both efficiency and quality in processes while also ensuring continuous access to data. Paperless production is facilitated by fully digitized Q-Checks and a management cockpit, which work together to ensure continuous improvement on the shop floor. ROTZINGER also offers system integration services to help organizations implement the software in a step-by-step manner. Additionally, customers who sign a maintenance contract can take advantage of ongoing updates and advancements to the Digital Software Suite. The service experts will be at interpack to support customers with any questions regarding the company’s service support.

Learn more about the ROTZINGER Group’s packaging and processing portfolio and meet the team from May 4 to 10 at our booth C07 in hall 1 at interpack in Duesseldorf.

UK shopping baskets become healthier as food and drink manufacturers cut down on sugar, salt and calories

New Kantar Worldpanel data, released by the Food and Drink Federation (FDF), shows the average UK shopping basket has become healthier within recent years. This is based on metrics developed by government to enable nutritionists to ‘score’ food, looking at a whole range of factors from sugar to protein to fruit and vegetable content.

This is largely due to the food and drink industry making changes to support balanced diets, including improving the recipes of our favourite brands, innovating with new healthier options and providing appropriate portion sizes. Products from FDF members now contribute 13% fewer calories, 15% fewer sugars and 24% less salt to the average shopping basket than they did eight years ago.

The Food and Drink Federation’s chief scientific officer Kate Halliwell said: “Our companies are committed to helping people live healthy lives and we recognise the important role we play in offering a range of healthier choices for consumers. These latest figures show the fantastic achievements the UK food and drink industry continues to deliver, throughout a challenging period of uncertainty, and we should celebrate this.

“Manufacturers have continued to innovate and bring new healthier products to market. Whether that’s adding more vegetables to a pasta sauce, reducing sugar in a breakfast cereal or enabling you to choose a smaller portion of cake, this has had a real demonstrable impact on the average shopping basket, supporting the nation to have access to a healthy balanced diet.”

The latest data also found that the FDF’s largest companies have managed to achieve improvements on nutrition which are around four times that of smaller companies.

Kate added: “This data demonstrates that more support is needed to help smaller businesses match the innovation and output of the larger companies. With 97% of the food and drink industry made up by small to medium sized companies, these companies can play an important role in providing healthier options but many do not have the resources, or technical expertise to reformulate their products.

“The industry stands ready to work with government to drive further innovation within our sector, and to work in partnership to power the health of our workforce and communities across the UK.”

Chief Executive of the British Nutrition Foundation Elaine Hindal said: “Reformulation has an important part to play in helping people to have healthier diets, through improving the nutrient profile of food. Although on its own reformulation can only take us so far on the journey towards supporting healthier and more sustainable dietary patterns, it is encouraging to see the progress shown by this new data and that there is consideration for how to ensure all businesses – regardless of size – get the support they need to improve the nutrient profile of their products.”

Highland Spring Group’s net-zero target approved by the Science Based Target initiative

Highland Spring Group, the producers of natural source waters, has had its science-based net-zero target approved by the Science Based Target initiative (SBTi) under the new Net-Zero Standard.

In 2021, the business announced its ambitious climate target to reach net-zero emissions by 2040 and set credible and robust science-based targets. The Group says it continues to work collaboratively with suppliers to explore and maximise opportunities to reduce emissions across its entire operations, from source to shelf.

Simon Oldham, Managing Director, Highland Spring Group, said: “Since the business was founded over 40 years ago, our core purpose has been to provide healthy hydration in an environmentally sustainable way. The SBTi verification is an important milestone on our journey to net-zero and demonstrates our commitment to tackling climate change.

“We recognise the vital role companies must play in helping achieve transformation at the pace and scale needed to limit global warming to 1.5oC and we will continue to work hard on our strategy to create a positive impact for people, society and the planet.”

Highland Spring Group’s targets are as follows:

Overall Net-Zero Target

- Highland Spring Group commits to reach net-zero Greenhouse Gas (GHG) emissions across the value chain by 2040 from a 2019 base year.

- Highland Spring Group commits to reduce absolute scope 1 and 2 GHG emissions 50% by 2030 from a 2019 base year. Highland Spring Group also commits to reduce absolute scope 3 GHG emissions 46.2% within the same timeframe.

- Highland Spring Group commits to reduce absolute scope 1, 2 and 3 GHG emissions 90% by 2040 from a 2019 base year.

BrewDog appoints first chief supply chain officer

BrewDog has appointed Chris Fielden as its first chief supply chain officer. The new role will cover all aspects of sourcing, production, packaging and distribution for BrewDog beers and spirits.

Chris joins BrewDog from Warp Snacks, the company behind the Eat Real and Proper Popcorn snacking brands, where is he is currently supply chain director.

Prior to that Chris spent over six years in a similar role at Innocent Drinks where he was responsible for establishing Innocent’s super sustainable production site in the Netherlands.

Chris began his career at PepsiCo where he had multiple roles over a period of ten years, including running the company’s juices business in Europe.

“I am very excited about joining BrewDog,” said Chris Fielden. “It’s a company that wants to do business the right way and that’s really important to me. I love the product and I love the company’s people, planet, beer ethos.”

James Watt, BrewDog CEO, said: “We’re really lucky to have someone of Chris’ calibre and experience join us. This is a new role, reflecting the continuing growth of the business and the ambitions we have for the future.”

Chris will join BrewDog in mid-May.

Axia Spirit appoints Craftwork as UK distributor

Axia Spirit has announced a new distribution partnership with UK drinks distributor Craftwork.

Craftwork is now responsible for the distribution of the extra-dry mastiha from Greece throughout the UK. Craftwork will support Axia’s existing key on-trade accounts including The Botanist, The Real Greek and The Blind Pig, as well as helping the new and vibrant addition to the white spirit category to reach a wider UK audience.![]() Commenting on the announcement, Mark Dawkins, founding director at Craftwork, said: “When a new brand wants to effectively create a new (sub)-category, it needs to have everything: premium and attractive packaging, great liquid, a great story, the right strategy and investment levels, and the right team of people behind it. Axia has all of this.

“We are very excited by every aspect of this partnership and are already enjoying working with Tony and the team. The reaction to Axia is already extremely encouraging.”

Axia CEO Tony Chvala added: “We couldn’t be more thrilled to have Mark and Craftwork as our distributor that will build off of a solid base in the UK market since our launch in 2021. Their team is uniquely aligned with our growth plans and we look forward to supporting them.”

Commenting on the announcement, Mark Dawkins, founding director at Craftwork, said: “When a new brand wants to effectively create a new (sub)-category, it needs to have everything: premium and attractive packaging, great liquid, a great story, the right strategy and investment levels, and the right team of people behind it. Axia has all of this.

“We are very excited by every aspect of this partnership and are already enjoying working with Tony and the team. The reaction to Axia is already extremely encouraging.”

Axia CEO Tony Chvala added: “We couldn’t be more thrilled to have Mark and Craftwork as our distributor that will build off of a solid base in the UK market since our launch in 2021. Their team is uniquely aligned with our growth plans and we look forward to supporting them.”

Pernod Ricard to acquire majority stake in Skrewball

Pernod Ricard USA has signed an agreement for the acquisition of a majority stake in Skrewball, the world’s first super-premium peanut butter flavored American whiskey.

Founded in 2018, by Steven and Brittany Yeng, Skrewball was the first peanut butter flavored whiskey that offers a smooth, nutty taste. The winning combination has since been established as a consumer favorite in the flavored whiskey category, with the brand surpassing the symbolic milestone of half-a-million nine-liter cases sold in 2022.

The partnership adds a complementary brand to Pernod Ricard’s comprehensive portfolio of iconic spirits and wine brands and a perfect opportunity to continue building on its longstanding consumer centric and premiumization strategy. It comes on the back of the successful launch of Jameson Orange into the flavored whiskey category last year.

Flavored whiskeys appeal to a wide range of consumers, going beyond traditional whiskey lovers. It remains one of the fastest growing spirits categories in the US, representing a quarter of the overall whiskey sales in the world-leading market.

“Skrewball has proven its uniqueness and success with a large audience, so we are delighted to have this brand as part of our portfolio,” says Ann Mukherjee, chairman and CEO of Pernod Ricard North America. “With a product that brings an iconic American flavor to the spirits world, Steven and Brittany have found a true point of difference in the category. We are looking forward to unlocking the magic of this brand and a successful journey ahead.”

“It’s overwhelming to see how far we’ve come with a ‘screwball’ idea and a dream,” declare Steven and Brittany Yeng. “We are very excited to see what the future holds for this brand under Pernod Ricard. The engine behind the company – its strategy, global reach and brand building expertise – will greatly support in taking the brand to new heights and we are excited to see it soar.”

Debevoise & Plimpton LLP acted as legal advisor to Pernod Ricard. Perella Weinberg Partners acted as financial advisor to Skrewball and the founders and Latham & Watkins LLP acted as their legal advisor.

Bearings & Drives signs exclusive distributor deal with CeramicSpeed

As we are all aware, in the food and beverage industry, uptime and reliability are everything. Production equipment requires food-grade certification, and any breakdown will cause costly repairs and production stops. To further strengthen its support to the industry, NW based bearings firm Bearings & Drives Ltd, has become the sole distributor of the industry leading CeramicSpeed Insulate ball bearings, introducing to the UK market the latest technology in operational efficiency, allowing UK customers day to day direct access to these products from their warehousing facilities.

Constantly at the forefront of technological development and innovation, CeramicSpeed is a dedicated and leading supplier of hybrid ball bearings. With a strong presence in the European market, they are rapidly becoming the industry’s most trusted supplier of advanced bearing solutions. CeramicSpeed Insulate ball bearings are custom-made for electrical motors and a guarantee against damage caused by stray currents.

Steve Bacon,Sales Director at Bearings & Drives, explains the significance of the supply arrangements for the UK food and drink industry: “We are thrilled to become the UK distributor for such a ground-breaking product. CeramicSpeed Insulate Hybrid ball bearings are the future across all industries, including manufacturers of electrical motors. The demand for stronger, more durable and longer-lasting bearings for electrical motors is on the rise – and in many applications, conventional steel balls in motor bearings simply can’t compare.

“When we reviewed CeramicSpeed Insulate in action in Denmark we saw the immediate benefits that we can bring to our manufacturing clients here in the UK. Taking for example how the product range brought significant efficiencies to a leading Danish dairy products manufacturer. The manufacturer faced sizeable issues with the durability of steel bearings they were using in a specific motor. The products manufactured by the dairy contain many small particles that penetrate the bearings subsequently reducing the bearing life. Along with high bearing temperatures this led to many control shutdowns and became detrimental to efficient operation.

“CeramicSpeed Insulate bearings are non-conductive as the ceramic balls in the bearing have a resistivity of 15 kV per mm. The Insulate series is the best defence against damage caused by stray currents. In addition to being protected from the passage of electrical currents, the operating temperature in hybrid bearings is approximately 10-20 °C lower than conventional bearings. By using these, the dairy has now reduced the bearing temperature with 15ºC increasing lubricant life and decreasing production shutdown considerably. The CeramicSpeed bearings with their higher resistance towards corrosion and contamination, increased the bearing life of the bearings by 400%.”

Anders Thormann, Managing Director at CeramicSpeed explains why they chose Bearings & Drives as their exclusive partner for CeramicSpeed Insulate: “Bearings & Drives helped us to break through in the UK food and beverage category in 2017, and the knowledge gained on our products by their team since then puts them in a unique position to take the next step in distributing CeramicSpeed products in the UK.”

From their base in Congleton, Cheshire Bearings and Drives serves its national client base with industrial Maintenance, Repair and Operations products from globally recognised manufacturers of Bearings, Power Transmission, Industrial Gearboxes, Motors, Tools & Consumables. Drawing on their vast experience of customer requirements, their products and services have been developed for all types of industries including Food, Paper, Recycling, Distribution, Quarrying and Plastics.

The business offers single source supply, including managed inventory services, to streamline your ordering process, reduce downtime and improve production efficiency – creating considerable cost savings. Their industry leading Repair Services cover Motors, Gearboxes & Pumps. Available 24/7, the team of highly skilful engineers is on hand to deliver advice and engineering solutions.

For more information, visit https://bearingsanddrives.co.uk

Macpac: 50 years old and growing stronger every day…

From a small-scale humble start-up manufacturer in 1973, Macpac has grown to be the innovative and successful thermoforming packaging company it is today – and one of the UK’s largest privately-owned manufacturers in its sector.

2023 sees Macpac celebrating its milestone anniversary of 50 years, and we could not be prouder or more excited to celebrate all that Macpac has accomplished during this time in partnership with employees, clients, and industry partners.

This half a century of conceiving, designing, and manufacturing packaging is no small feat, particularly when taking into consideration how we have had to evolve with such turbulent times and demands, driven inexorably by climate change and environmental concerns, fuelled by a powerful and growing environmental lobby.

This major achievement is the result of the combined efforts and hard work of every individual within Macpac and is more remarkable for a privately-owned manufacturer to not only survive but thrive within a packaging sector that is notorious for its short-stay players, where there are numerous acquisitions, take-overs, and mergers.

Through two generations from father to son, Macpac has consistently delivered excellent customer service and provided packaging in a timely and cost-effective manner during a time that has seen a tumultuous evolution in packaging design and advances in materials technology. Testimony to this success is the number of customers that have remained loyal to the company over several decades.

The early days…

In 1973 the company was founded by Chris Kershaw, father of the current owner and Managing Director, Graham Kershaw. The company was born out of the demand to produce packaging for Dinky Toys and Meccano and operated on the first floor of an old printing mill. With the invention of ‘thermoforming’, growth was rapid and in the 1970’s the business re-located to Macclesfield, out of which the name ‘Macpac’ was born.

Expansion…

The business continued to expand throughout the 1980’s, with a further move to Bredbury in Stockport due to outgrowing the Macclesfield site. In 1990 Macpac gained the ISO9001 accreditation for the development processes put in place for tooling development.

A low point in Macpac history came in 1996 when a devastating fire at the Bredbury factory prompted the move to the current address on the Heaton Mersey Industrial Estate in Stockport. Occupying just a single industrial unit with a modest 4 thermoforming machines on site, Macpac continued to operate and grow.

Keeping it in the family…

In 1997 Chris Kershaw’s son, Graham, returned to the family business after graduating from university and working overseas for 10 years on robot control systems. It is this interest in manufacturing processes & his commitment to the environment that would be a guiding factor in the direction that Macpac would follow in the years ahead, influencing the green credentials of the company’s packaging designs and choice of materials.

By 1998 Macpac realised that to achieve increased productivity it had to modernise its processes, therefore introducing Computerised Numerical Control machines (CNC’s) into its toolroom. This departure from traditional cast aluminium toolmaking provided highly accurate CAD/CAM machining and gave a distinctive competitive edge whilst speeding up the whole process. Over the following years Macpac would continue to invest heavily in supporting the tooling manufacture process which in turn plays an important part in feeding the thermoforming machines.

The next generation…

In 2000 Chris Kershaw decided to take a step back from the business and Graham became the new Managing Director of Macpac. This was to be a turning point in Macpac’s history – with an injection of new investment and forward-thinking ideas, to grow what was already a well-established business, into the force it has become today.

RPET takes centre stage…

In 2003, there was a stampede to move from PVC due to recycling issues and heightened concerns for the environment. Macpac was to be a forerunner in the application of its preferred replacement – Recycled PET (R-PET) – promoting the uptake and use of the material across a wide range of key markets. In 2005 Macpac entered the medical/pharmaceutical sector, naturally using R-PET as the choice of material in its design of the very first thermoformed dosage pill tray, which was to revolutionise the administration of tablets to millions of patients. R-PET has now become the most widely used of all thermoforming materials and by 2023 makes up over 90% of the material Macpac processes through its factory.

The scalable process

By 2008 and following sizable investment in new thermoforming equipment, Macpac had doubled the size of its factory with the acquisition of adjoining units, with later expansions to the site for larger raw materials and finished goods warehousing. In 2010 and a further investment of £750,000 in new machinery and staff, the company achieved BRC/IOP accreditation which it has proudly held ever since.

2011 saw Macpac make a big step forward with the acquisition of Hamilton Packaging. This purchase expanded Macpac’s customer portfolio and introduced Macpac to new markets they had not been involved with previously.

Working with German machine manufacturers Illig, Macpac, always being innovative and looking to improve efficiencies, helped develop a new rewind system for their machines. 2013 saw Macpac install the first Illig 74 down-stacking machine ever made incorporating this new design – this new machine allowed for a reduction of tooling costs without compromising on production efficiencies.

Innovation at our core…

Innovation is at the centre of Macpac’s ethos; this is evident with a plethora of awards gained over the past few years:

Macpac saw double in the year 2000 – winning both the prestigious Starpack ‘Gold Award’ for its packaging design to house a Carbon Monoxide detector, and with a ‘Bronze Award’ for technical innovation.

In 2014 Macpac won another Starpack Award – this time ‘Silver’, for a patented clam pack design called ‘Surecel’ which offered a range of high security, tamper-evident clam packs, without the requirement for specialist machines to close the packs, nor scissors to open them.

During 2015 Macpac received a Starpack ‘Bronze Award’ for ‘Snap In’, another patented solution. This clever design offered the opportunity to lock a thermoformed part to another substrate, such as board or acetate sleeve, and was perfectly conveyed when used for the popular Orchid retail market in Tesco.

A year later Macpac was awarded ‘Best Innovation Award’ at the 2016 Gro South Horticultural show for its Large Letter Pack design enabling plants to be sent through the post at the Royal Mail’s Large Letter rate.

In 2020 Macpac won the ‘Special Award for Covid 19 Response’ at the Railway Industry Awards. This was for the design and manufacture of special, thermoformed visors that could be uniquely fitted over hard hats and were produced in record time for the Network Rail workforce to use during the height of the Covid outbreak. The designing, prototyping, manufacturing of tooling and then forming of the visors took place over the Easter Holiday weekend, during a challenging time for all, whilst adapting and coming to terms with new working rules brought about by the pandemic.

Never standing still, Macpac added a further string to their bow in 2022 by installing the very first down-stacking machine with punch and die capabilities in the UK, giving Macpac even more manufacturing options to better service customers’ demands.

A major attraction of Macpac is the company’s personal attention to detail, working with customers to ensure they understand the initial brief and meet their customer’s needs relating to bespoke design, budget, and sustainability. From initial concept to finished design and manufacturing of tooling all under one roof, Macpac has the flexibility to manufacture from as little as 1000 units up to many millions, covering all sectors of industries, each with their own nuanced specifications. Whether dealing with food projects requiring a fast turnaround to meet tight in-store launch dates, wax melt projects with quirky designs, or highly technical, long-term pharmaceutical projects, Macpac has the knowledge and experience, reflected in their solid growth as a second-generation family business.

In 2023 Macpac is 50 years young and counting – with passion and family values at the core, celebrating half a century of proven dedication in design and manufacture, we are very much looking forward to what exciting new challenges lie ahead…

London Packaging Week organisers launch key survey

Leading multi-format event organiser Easyfairs has committed to taking the packaging sector’s temperature in the coming weeks by launching a brand-new survey.

London’s vibrant home for packaging innovation and design, London Packaging Week, is seeking to canvas the opinion of suppliers, designers, packaging developers, marketers, and founders, as it continues to identify the major forces and emerging trends that will reshape luxury over the next decade.

The five-minute, 10-question survey looks into which influential brands, organisations, and external factors are making waves – from manufacturing to consumerism.

Renan Joel, Managing Director, Packaging at Easyfairs, said: “This is an opportunity to help shape an already renowned event and allow us to continue creating a dynamic and inspirational offering that drives packaging innovation, business and connections at the heart of the UK’s luxury and consumer products markets.

“Unequivocally, our performance is contingent on the quality of our listening. It qualifies us to connect the dots between trust and relationships, whether between individuals, an organisation and its customers, or stakeholders.

“It enables us to look audiences in the eyes and guarantee a level of interest they relish.”

LPW, scheduled to take place on September 21 and 22 at the ExCel London, will, no doubt, be awash with of brands, innovators, designers and creators looking to study what drives the success of prestige brands innovating to come up with a league of creative and sustainable solutions.

“Packaging matters more than ever,” added the Easyfairs chief. “In a world of disparate alternatives, consumers choose to express themselves with brand choices that reflect their values.

“London’s vibrant home for packaging innovation and design will walk you through the entire immersive process, where the right materials and shapes are matched to the desired sensory cues that trigger a positive response in the consumer’s mind. Quite simply, there is no other exhibition or observer of the luxury industry whose insights are more useful, accurate and packed with smart predictions for the packaging sector. LPW will, once again, show that it understands the mindset that creates luxury’s timeless value.”

The short survey comprising 10 key questions can be found here.