Diageo sells Safari to Casa Redondo

Morrisons partners with Sea Forest to fast track lower methane beef

Exclusive UK distributor named for Brad Pitt & the Perrin Family’s The Gardener Gin

Carlsberg reaches agreement to acquire Britvic in £3.3bn deal

Carlsberg has reached an agreement to acquire soft drinks business Britvic in a deal that values the latter at approximately £3.3 billion, and gives the brewing giant an opportunity to grow its UK operations and bottling relationship with PepsiCo.

Carlsberg intends to create a single integrated beverage company in the UK, to be named Carlsberg Britvic and led by a management team comprised of individuals from each of Carlsberg, CMBC and Britvic. The enlarged business will have a portfolio of leading brands across the beer and soft drinks categories. Britvic shareholders will vote on the takeover at a general meeting. Following completion Carlsberg is expected to become the largest PepsiCo bottling partner in Europe.Ian Durant, Non-Executive Chair of Britvic, said: “Britvic is an outstanding business with a strong heritage built on its portfolio of family-favourite brands, long-standing customer relationships, a well-invested supply chain infrastructure and a fantastic team of people across multiple markets. All these factors have supported a consistent track record of delivery for Britvic’s stakeholders over a sustained period of time.

“The proposed transaction creates an enlarged international group that is well-placed to capture the growth opportunities in multiple drinks sectors. Crucially, to remain competitive at a time when the market is being shaped by the trend of increasing consolidation among bottling partners, Carlsberg’s agreement with PepsiCo provides the combined group with a strong platform for continued success.

“The Board of Directors believe that the strategic merits of this offer are compelling, and the offer also provides shareholders with the opportunity to receive the certainty of cash consideration that reflects the current strength and medium-term prospects of the Britvic business.

“It also recognises the challenges of achieving an appropriate future rating and valuation for Britvic versus its historical range of trading multiples, alongside less certain long-term alignment with regard to its PepsiCo bottling business. Therefore, the Board is unanimously recommending the offer to our shareholders.“

Jacob Aarup-Andersen, CEO of Carlsberg, said: “With this transaction, we are combining Britvic’s high-quality soft drinks portfolio with Carlsberg’s strong beer portfolio and route-to-market capabilities, creating an enhanced proposition across the UK and markets in Western Europe.

“The proposed transaction is attractive for shareholders of Carlsberg, supporting our growth ambitions and being immediately earnings accretive and value accretive in year three. We are excited about expanding our global partnership with PepsiCo and believe that the longer-term opportunities will be very beneficial for both companies.

“We are pleased that the Britvic Board is unanimously recommending our offer to Britvic Shareholders. We look forward to welcoming Britvic’s employees into the Carlsberg family and creating an exciting, combined company for all employees.

“We are committed to accelerating commercial and supply chain investments in Britvic, and we are confident that Carlsberg Britvic will become the preferred multi-beverage supplier to customers in the UK with a comprehensive portfolio of market-leading brands.“

Silviu Popovici, CEO of PepsiCo Europe, said: “We are looking forward to building on our long-standing and successful partnerships with both Carlsberg and Britvic. We believe that the combination of Carlsberg and Britvic will create even stronger sales and distribution capabilities for our winning brands in important markets. We look forward to continuing to expand the partnership into further important markets in the future.”

Sainsbury’s invests in new AI vet tech to enhance animal welfare on dairy farms

European manufacturer of food cans, ends, and closures, Eviosys, to be acquired

Visitor registration opens for the next edition of West Africa’s leading manufacturing exhibition and conference

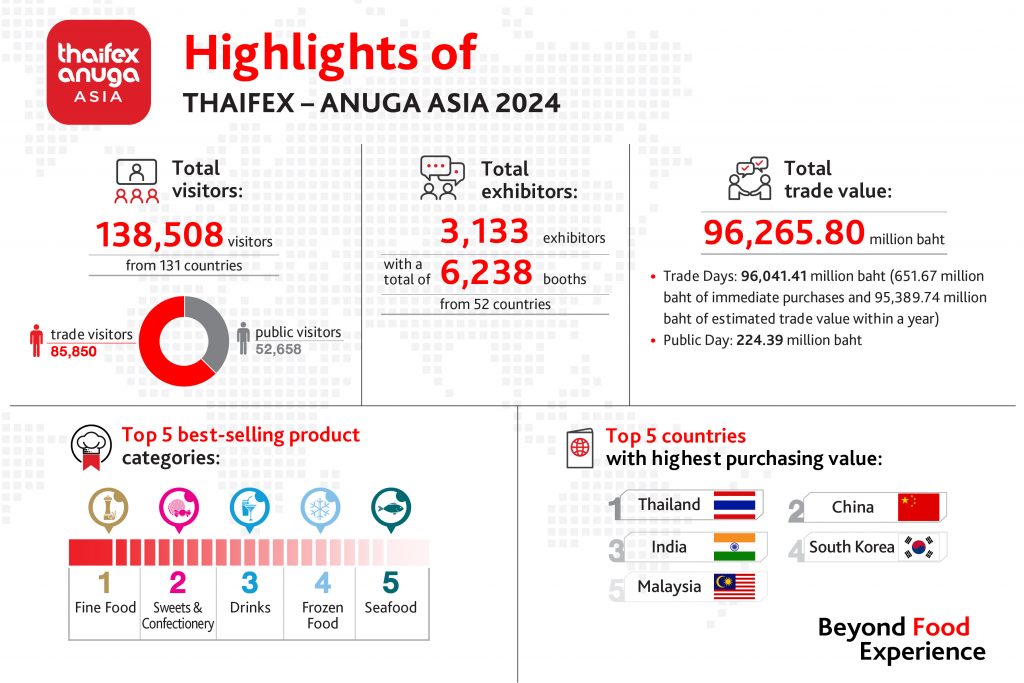

THAIFEX – ANUGA ASIA 2024 achieved remarkable success connecting global food & beverage businesses for vibrant trade networking

NOW & BEYOND

THAIFEX – ANUGA ASIA 2024 gathered innovations and trends in the food and beverage industry that cater to current and future lifestyles, focusing on health, sustainability, and emerging trends, to help businesses respond to market demands. The activities included THAIFEX – ANUGA Future Food Market, THAIFEX – ANUGA Halal Market, THAIFEX – ANUGA Organic Market, THAIFEX – ANUGA Startup, THAIFEX – ANUGA tasteInnovation Show, and THAIFEX – ANUGA Trend Zone.

OPPORTUNITY BEYOND

THAIFEX – ANUGA ASIA 2024 brought together exhibitors in the food and beverage industry from 52 countries across various regions, including East Asia, ASEAN, Europe, North America, Latin America, Middle East, and Australia, to meet with 85,850 trade visitors for fruitful business negotiations, resulting in the greater opportunity for strategic

partnerships and collaborations.

INSPIRATION BEYOND

THAIFEX – ANUGA ASIA 2024 was also a holistic learning hub for exploring new experiences and enhancing knowledge in the food business and marketing through activities, exhibitions, seminars, and consulting services, all designed to help businesses succeed in the future. There were several fascinating activities such as Thailand Ultimate Chef Challenge 2024, Future Food Experience+, Food Arcade, Export Clinic, Thai SELECT Pavilion, and Thai Halal Pavilion.

See you again! Be a part of our great success at THAIFEX – ANUGA ASIA 2025 from 27 – 31 May 2025 at IMPACT Muang Thong Thani, Bangkok, Thailand.

NOW & BEYOND

THAIFEX – ANUGA ASIA 2024 gathered innovations and trends in the food and beverage industry that cater to current and future lifestyles, focusing on health, sustainability, and emerging trends, to help businesses respond to market demands. The activities included THAIFEX – ANUGA Future Food Market, THAIFEX – ANUGA Halal Market, THAIFEX – ANUGA Organic Market, THAIFEX – ANUGA Startup, THAIFEX – ANUGA tasteInnovation Show, and THAIFEX – ANUGA Trend Zone.

OPPORTUNITY BEYOND

THAIFEX – ANUGA ASIA 2024 brought together exhibitors in the food and beverage industry from 52 countries across various regions, including East Asia, ASEAN, Europe, North America, Latin America, Middle East, and Australia, to meet with 85,850 trade visitors for fruitful business negotiations, resulting in the greater opportunity for strategic

partnerships and collaborations.

INSPIRATION BEYOND

THAIFEX – ANUGA ASIA 2024 was also a holistic learning hub for exploring new experiences and enhancing knowledge in the food business and marketing through activities, exhibitions, seminars, and consulting services, all designed to help businesses succeed in the future. There were several fascinating activities such as Thailand Ultimate Chef Challenge 2024, Future Food Experience+, Food Arcade, Export Clinic, Thai SELECT Pavilion, and Thai Halal Pavilion.

See you again! Be a part of our great success at THAIFEX – ANUGA ASIA 2025 from 27 – 31 May 2025 at IMPACT Muang Thong Thani, Bangkok, Thailand.